NTN Bearing Burnout Inspection Analysis and Prevention Methods

Source: Bearing Network | Date: January 22, 2014

NTN bearings are essential components in the rear axle drive system of vehicles. They are designed to handle torsional forces, torque, and some impact loads. Typically, the axle is made from carbon alloy hardened steel, which undergoes induction hardening. The hardened layer usually has a depth of 4–6 mm with a hardness of 50–55 HRC. During operation, NTN bearings can sometimes experience burnout, which significantly affects the quality of the bearing and its parts. Studies have shown that the burnt areas often occur around coil 225, where the fault characteristics are most evident. This indicates that the location of the burnout is closely related to the design and performance of the induction coil. When it comes to heating during the induction process, there are several ways heat is generated and dissipated: 1. **Radiation to the surroundings**: The induction coil is typically insulated using varnish and fiberglass cloth, minimizing heat loss. This method ensures even heat distribution and less impact on the sensor. 2. **Cooling water**: Some systems use cooling water for heat dissipation. At temperatures between 0–180 degrees, the cooling water flows smoothly, maintaining an effective temperature. However, beyond 180 degrees, due to the extended flow path, the water temperature rises, reducing the efficiency of heat exchange. This can lead to localized overheating, especially near areas like 225 degrees, which may cause the primary induction coil to burn out. 3. **Heat conduction through plates**: Certain sections of the induction coil may have lower current density or smaller cross-sections, leading to uneven heat distribution. Areas such as 0–90 degrees and 270–360 degrees tend to have better thermal conductivity, while the 90–270 degree range experiences higher temperatures, potentially causing burn marks on the coil. The difference in heating current across these regions contributes to varying degrees of burnout. To prevent such issues, proper maintenance and monitoring of the induction heating process are crucial. Ensuring adequate cooling, regular inspection of coils, and optimizing the heating cycle can significantly reduce the risk of burnout. In addition to this, understanding the factors that contribute to bearing failure is essential for maintaining the reliability of mechanical systems. Proper installation, lubrication, and periodic checks can help extend the life of NTN bearings and other types of rolling bearings. If you're interested in learning more about bearing technology, check out our other articles on topics such as heat treatment deformation prevention, bearing disassembly methods, and common terminology used in the industry.

**Related Bearing Knowledge** Learn how to prevent heat treatment deformation in bearings, understand the classification of rolling bearings, and discover the best practices for inspecting and maintaining bearings. For more information, visit [China Bearing Network](http://www.chinabearing.net). Previous Article: The demand for SKF bearings in wind energy applications. Next Article: Common terminology and definitions of rolling bearings (Part 6)

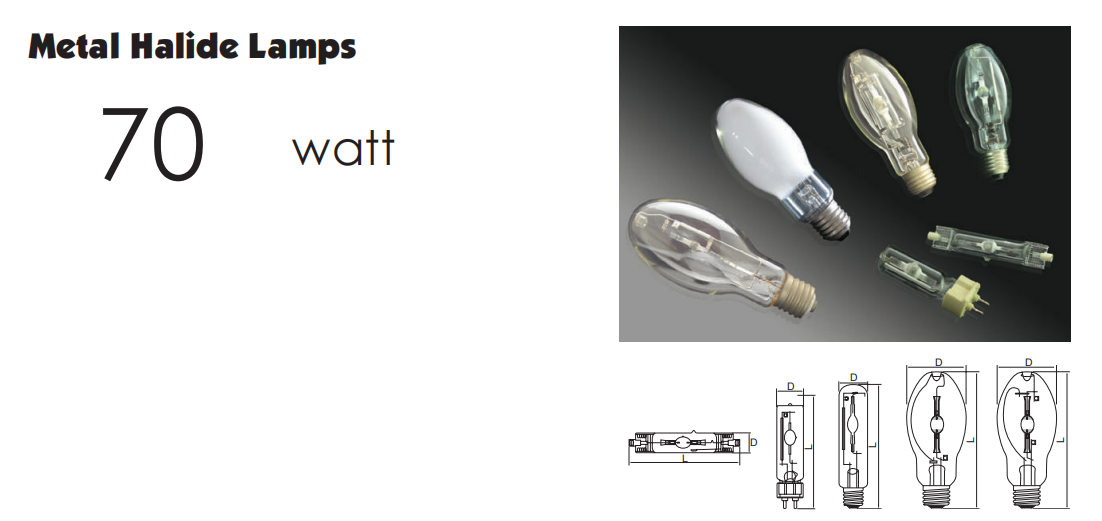

Metal Halide Bulb

A Metal Halide Bulb, also known as a Metal Halide Lamp, is a type of gas discharge lamp that produces light by passing electrical currents through a mixture of mercury and metal halides. It is known for its high luminous efficacy, long lifespan, and good color rendering index, making it a popular choice for various industrial and commercial applications

4

Key Features

- High Luminous Efficacy: Achieves light efficacy ranging from 65 to 140 lm/W.

- Long Lifespan: Typically lasts between 5000 to 20,000 hours.

- Good Color Rendering: Provides a high color rendering index (Ra) of 65 to 95, offering accurate color representation.

- Compact and Stable Design: Available in quartz and ceramic versions, offering structural stability and durability.

Applications

Metal Halide Bulbs are widely used in:

- Stadiums and Sports Arenas: For their high output and ability to provide optimal lighting conditions.

- Construction Sites: Ensuring safety and visibility during nighttime operations.

- Parking Lots and Loading Docks: Providing bright, consistent lighting for extended periods.

- Commercial Buildings: Enhancing the aesthetic appeal and functionality of indoor spaces

.7

metal halide bulb,400 watt metal halide bulb,250 watt metal halide bulb,1000 watt bulb,100 watt metal halide bulb

Yangzhou M.T. New Energy & Lighting Group Co., Ltd. , https://www.mtstreetlight.com