Properties – residential, commercial, and industrial – run on electricity. Whether it is lighting, air conditioning, or the internet of things (IoT), all basic to complex tasks require current. This passes through electric cables, each of which have a different cable sizing based on their use. Measured in American Wire Gauge (AWG), the smaller its number, the larger the cable (and vice versa). However, if excess current flows through a small cable, the wiring can be impaired permanently. This is why it is essential for one to choose the right power cable size. But how can you do so? Given below are 3 ways you can identify the right electric cable wire size.

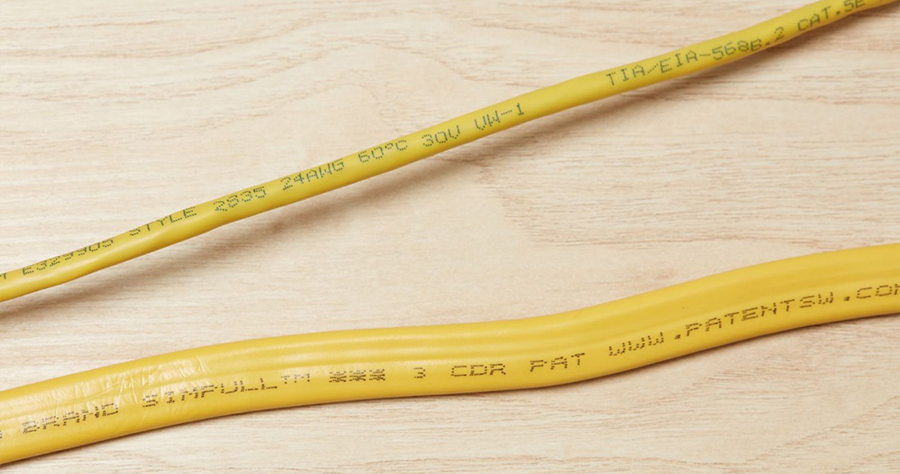

1. Look at Cable Insulators

Text or numbers are printed on each cable to denote their size. Generally, the last numbers represent the wire’s AWG.

2. Incise the Wire

Use a wire cutter and make a cut that is perpendicular to the run of the wire. If not done this way, you may cut the inside wiring and get the wrong diameter measurement.

3. Measure the Diameter

The diameter of the cross section must be measured in inches. Once that is done, divide the number by 45.

But what are the ideal electrical cable sizes that you can use, along with their voltage and different types? More on that below.

Ideal Electrical Cable Sizes, Their Voltage, and Different Types

Residential, commercial, and industrial properties generally have electric cable sizing of 12 and 14 gauges. All wires have some resistance; this is directly proportional to the length of the wire and inversely proportional to its diameter. Wires experience a certain voltage drop when electric current flows through them. However, the smaller its diameter or longer the wire length, the higher the voltage drop. This is why you must choose the right types of cables based on their use, some of which are listed below:

- Power Cables

- Rubber Cables

- Electric Panel Cables

- Armoured Cables

- Fire-resistant Cables

- Halogen-free Cables

- Solar Cables

- Aluminium Cables

- Solar Cables

It is also noteworthy that such cables are made with different materials like PVC, tinned copper, thin wall, or double insulation. But which cables should you choose for your residential, commercial, or industrial property?

KEI Cables – India’s Leading Cable Manufacturer

KEI cables are market leaders in wire and cable solutions. Headquartered in New Delhi, we have expanded operations across India over the last 6 decades. Whether you are looking for extra-high voltage cables or low voltage cables, communication or instrumentation cables, fire resistant or solar cables, we manufacture them all. To know more, send us an email on or visit www.kei-ind.com to see our whole sproduct range.

Die casting is a metal casting process that involves forcing molten metal under high pressure into a mould cavity. The mould cavity, also known as a die, is typically made of hardened steel and is custom-designed to produce the desired shape of the final product.

The process begins with melting the metal, usually non-ferrous metals such as zinc, aluminum, magnesium, or copper alloys, in a furnace. Once the metal reaches the desired temperature, it is injected into the mold cavity at high pressure using a hydraulic or mechanical press.

The high pressure helps to quickly fill the mold cavity and ensures that the molten metal solidifies rapidly to produce precise and complex shapes with fine surface details. After the metal solidifies, the mold is opened, and the casting is ejected from the die.

Die casting is commonly used to produce a wide range of metal components and products with high dimensional accuracy, excellent surface finish, and tight tolerances. It is widely employed in industries such as automotive, aerospace, electronics, and consumer goods manufacturing.

alloy die casting,gravity die casting,gravity casting,high pressure die casting,pressure die casting

Taiyuan Simis Investment Casting Co., Ltd , https://www.precision-casting.biz